During the pharmaceutical sector, the journey from Uncooked elements to some concluded medication is a complex approach involving a number of important components. At the heart of this method may be the Energetic Pharmaceutical Ingredient (API), the compound liable for the therapeutic consequences of a drug. This text delves into the various elements of APIs, drug substances, impurities, pharmaceutical intermediates, and the intricate planet of pharmaceutical production.

Active Pharmaceutical Ingredient (API): The Core of Medication

The Energetic Pharmaceutical Ingredient, usually called API, is the first element in the drug that produces the intended effects. APIs are classified as the essence of any medication, pinpointing its efficacy and protection. They can be derived from different sources, like chemical synthesis, fermentation, or extraction from purely natural products. Inside the context of blend drugs, which include more than one active ingredient, Every API plays a specific function in addressing various elements of a problem.

API and Drug Material: A Closer Appear

Whilst the conditions "API" and "drug compound" in many cases are made use of interchangeably, they may have distinctive meanings in pharmaceutical production. The drug substance refers back to the purified chemical compound that will become the Energetic ingredient in the ultimate pharmaceutical product or service. It is the API in its isolated form before it is actually formulated right into a consumable drug, such as a pill, capsule, or injectable Remedy.

The production of drug substances involves demanding processes to ensure purity, potency, and security. These processes include things like chemical reactions, purification measures, and crystallization, all aimed at developing a drug material that satisfies rigid regulatory specifications.

Impurities in Pharmaceuticals: Identification and Regulate

Impurities are unwanted substances that could be present in APIs or drug substances. They will come up from many sources, together with raw products, manufacturing procedures, or degradation from the drug after some time. Controlling impurities is often a critical facet of pharmaceutical production, as they can have an affect on the safety and efficacy with the medication.

Regulatory organizations such as the FDA and EMA have stringent pointers for identifying and quantifying impurities in drug substances. Analytical tactics like chromatography and spectroscopy are used to detect and evaluate these impurities, making sure that they remain inside of suitable restrictions.

Pharmaceutical Intermediates: The Developing Blocks

Pharmaceutical intermediates are chemical compounds that happen to be produced through the synthesis of an API but are certainly not them selves Lively ingredients. These intermediates serve as developing blocks inside the multi-phase strategy Active Pharmaceutical Ingredient of API generation. The standard and security of intermediates are important, since they directly influence the final API’s purity and effectiveness.

Handling intermediates entails cautious monitoring of response conditions, purification steps, and storage prerequisites. Any deviation during the creation of intermediates may result in impurities or diminished yields of the final API.

Pharmaceutical Manufacturing: From Lab to Sector

Pharmaceutical producing is a complicated procedure that transforms APIs into consumable drug goods. It encompasses several levels, like formulation, blending, granulation, compression, coating, and packaging. Each phase is meticulously controlled to make sure the last products fulfills the needed technical specs for dosage, energy, and high quality.

Superior Production Practices (GMP) are the inspiration of pharmaceutical manufacturing, guaranteeing that goods are continuously developed and managed In line with high quality benchmarks. GMP covers all components of manufacturing, with the procurement of raw resources to the ultimate distribution from the product or service.

Quality Management and Assurance: Making sure Security and Efficacy

Excellent Manage (QC) and good quality assurance (QA) are integral factors of pharmaceutical manufacturing. QC requires screening and verifying which the Uncooked materials, intermediates, and finished solutions fulfill predefined specifications. QA focuses on the overall technique of checks and balances, guaranteeing which the producing process adheres to regulatory specifications and that any deviations are immediately tackled.

Pharmaceutical corporations devote closely in quality methods to mitigate hazards connected to impurities, contamination, and batch inconsistencies. Highly developed systems, which include real-time checking and system analytical technology (PAT), are increasingly getting used to improve excellent Regulate and streamline generation processes.

Conclusion

The creation of prescribed drugs is a complex interaction of science, technological know-how, and regulatory compliance. APIs sort the backbone of medicines, as well as their generation calls for meticulous Impurity focus to detail to be certain They are really Safe and sound and powerful. From your synthesis of pharmaceutical intermediates to the ultimate phases of drug manufacturing, Each individual phase is essential in offering large-quality medicines to clients. By knowing the intricacies of APIs and pharmaceutical manufacturing, we could value the endeavours driving every capsule, injection, or capsule that improves and saves life.

Edward Furlong Then & Now!

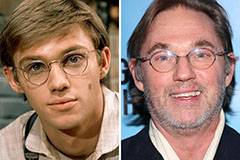

Edward Furlong Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Lisa Whelchel Then & Now!

Lisa Whelchel Then & Now! Dawn Wells Then & Now!

Dawn Wells Then & Now! Dolly Parton Then & Now!

Dolly Parton Then & Now!